My first site visit of the year was to Smith-Midland Corp. (OOTC:SMID). While interviewing management teams behind stocks on my buy list is one of the most valuable aspects of my research process, I also know that just as powerful can be the ability to see first-hand, through site visits, exactly how the company operates. The SMID on-the-ground due diligence was my continuation of information gathering; from phone to facility.

My first site visit of the year was to Smith-Midland Corp. (OOTC:SMID). While interviewing management teams behind stocks on my buy list is one of the most valuable aspects of my research process, I also know that just as powerful can be the ability to see first-hand, through site visits, exactly how the company operates. The SMID on-the-ground due diligence was my continuation of information gathering; from phone to facility.

The SMID site visit arose from our focus on stocks, such as NV5 Global (NVEE), that are benefiting from the U.S spending billions of dollars to rebuild/improve the infrastructure of roads, buildings, bridges and power generation grids.

As a matter of fact, we added NVEE to our snap back rally portfolio for this reason. The stock rose 25% after we published our interview with the company’s CEO, which can be heard here.

In 2016, I plan to build on this focus. After all, Peter Lynch found the time to visit hundreds of companies a year while managing the billion-dollar Fidelity Magellan fund from 1977 to 1990.

After more digging around, perhaps calling or visiting the company — which Lynch calls kicking the tires and does at least 500 companies a year — you should be able to deliver a brief monologue on why you think the stock is a winner.

A regular Premium contributor to Geoinvesting, William Xion, just published an excellent overview of SMID, which includes an industry overview of the precast concrete industry. You can read it here for a limited time as it compliments the following very well. Although SMID will have some exposure to cyclical trends in the economy, we think SMID is doing the right things to grow over the long-term. We would feel even stronger about their growth if the company is more aggressive on the marketing front and gains approval from more states and countries to sell its products.

Introduction to Smith-Midland

My first site visit of the year was to Smith-Midland Corp., a company that makes precast concrete products for the construction, transportation, and utilities industries.

“Precast concrete is a construction product produced by casting concrete in a reusable mold or ‘form’ which is then cured in a controlled environment, transported to the construction site and lifted into place. In contrast, standard concrete is poured into site-specific forms and cured on site.”

First, I identified the major risks ahead of the company’s upcoming Q4 report, which is due any day now:

- Quarterly variability in sales and earnings due to weather

- Quarterly variability in sales and earnings due to cyclical nature of served markets

30% of the company’s revenue is derived from wall sales, which include panels attached to walls on buildings and sound barrier walls along highways (the company’s “Slender Wall” product).

54% of sales are evenly distributed between safety barriers used to separate lanes on highways (J- HooksTM), pre-built structures like bathrooms and utility vaults that house equipment such as cable, telephone or traffic signal equipment, and for underground storage.

The rest of the company’s revenue comes from transportation fees and licensing revenue related to some of its main products. The company is attempting to increase the amount of revenue it earns from licensing.

I started buying SMID in the second half of 2015, after following it for a few years. I am not a huge fan of buying stocks in what appear to be super cyclical industries, but I decided to make an exception after gaining some confidence that the company’s exposure to some undeniable strong industry tailwinds and a more aggressive marketing strategy could reduce seasonality for the near-term.

These tailwinds included the long awaited passage of the highway bill on December 4, 2015 which “calls for spending approximately $205 billion on highways and $48 billion on transit projects over the next five years” and the utility industry scrambling to keep up with regulation to upgrade infrastructure. The company is also working on gaining approval to sell some of its products across more states (the company is currently in 40 states). In some ways, SMID and NVEE share the same “infrastructure” opportunity. SMID offers products, while NVEE offers project management services.

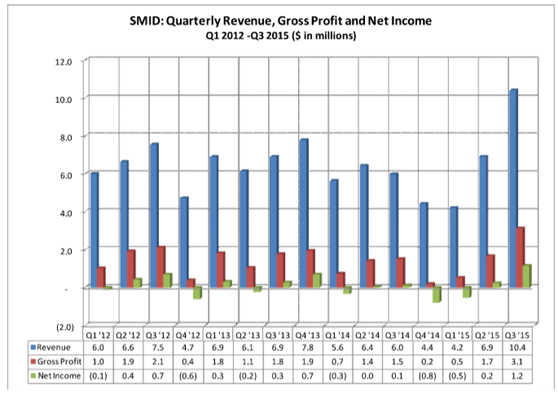

On November 12, 2015, an hour before the close, SMID reported blowout Q3 2015 results that exceeded even our lofty expectations:

- Total revenue of $10.4 million for three months ended September 30, 2015 was $4.4 million or 74.1% more than revenue generated in Q3 2014.

- Net income of $1,152,056 for Q3 2015, compared to net income of $112,490 for the same period in 2014, a 1,000%+ increase.

- Basic and diluted earnings per share were $0.24 and $0.23, respectively, for Q3 2015 vs. $0.02 basic and diluted earnings per share for Q3 2014.

Here is a look at SMID’s financial performance since Q1 2012.

SMID Shares Punished

The decline in the market early this year punished shares of SMID. The stock fell from $3.50 to hit a low of $1.77 on February 5, 2016. An institutional holder that exited its position likely applied pressure on SMID shares. Other investors probably bailed due to the constant harassing media commentary trying to get us all to believe we were heading for a 2008-like recession/crash.

It is comforting that the stock has been inching up from early year lows. Still, I decided that I needed to get more intimate with the company to see if my investment was safe.

Blue Skies Ahead?

I boarded a flight at 7:00 am out of Fort Lauderdale on Wednesday February 25, en route to Virginia, excited to prepare for my meeting with Rodney Smith, CEO, and William Kenter, CFO.

Unfortunately, the Wi-Fi on the plane was working for everyone except for me. My other plan – sleeping on the plane – was also a failure. I had to listen to a young man for the duration of the flight giving a sales pitch to an elderly man he just met. He was trying to raise a few million dollars for a company he worked for that was developing “revolutionary” technology to harness energy from asteroids. Count me in! All I could think of was: “this would be a perfect OTC Pump and Dump for Awesome PennyStockPicks.com to profile.” Thankfully, I think this site is now defunct.

I landed at Reagan National Airport at about 9.15 am and took a taxi (should have used an Uber) to Crystal City, just outside Washington D.C., checking in at a Hilton. My first order of business was to hitch a ride to a nearby DSW warehouse (for a little Peter Lynch research) to buy some construction boots, since I would be rummaging around SMID’s grounds that I was told were drenched in mud from heavy rain on Tuesday.

Rodney was unavailable in the morning, so two hours later, a friend of his picked me up to take I-66 to visit SMID headquarters in Midland.

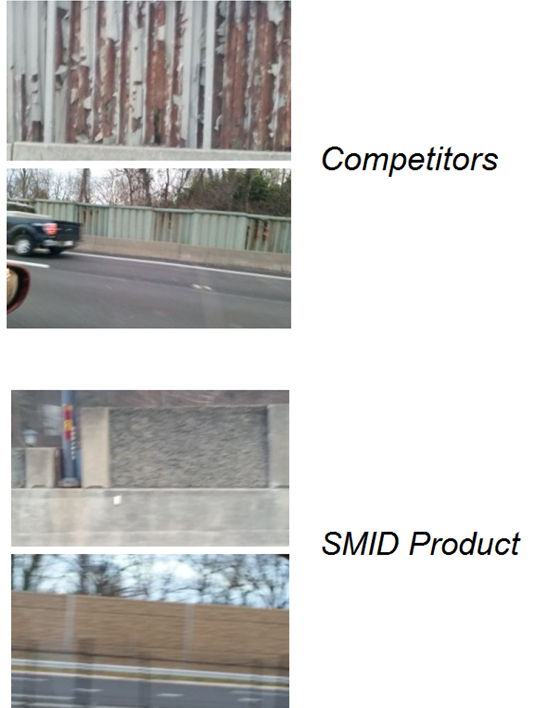

En route, I paid particular attention to the highway sound barrier walls lining the perimeter of the highway, since these are one of Smithland’s signature products. I was not sure if these barriers were SMID’s, something I would inquire about later. What I did notice was that some of the sound walls looked like they had been through World War III, while others looked to be in mint condition.

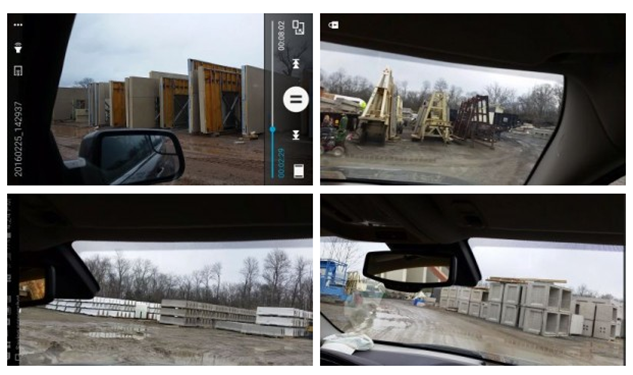

I arrived at the 39-acre facility at around 11:30 am. Before entering the building, I finally had the pleasure of catching a firsthand glimpse of some of SMID’s products (I would take a full tour later). The yard was full of product paid for and ready to ship.

It seemed that the company had no more space to store finished goods. I later learned the company just purchased 6 acres of adjacent land to accommodate for more storage, possibly a good sign that some of the business momentum from the company’s strong Q3 2015 has carried through to the fourth quarter and Q1 2016.

Next, I met with some of SMID’s management team.

Next, I met with some of SMID’s management team.

Before heading to lunch, I was eager to learn more about the competitive advantage(s) of SMID’s slender wall (panel) product, one of which was present where I was initially dropped off. I am convinced that that slender wall product is the real deal. Think of the product as a plug and play alternative to building an entire wall on site.

Although the raw material cost of both options may be similar, customers benefit from decreased expense related to labor and product sourcing activities. Furthermore, due to the slender wall’s light weight, more product can be shipped per load and savings can be passed on to the customer.

The wall can even be delivered with insulation “pre-installed.” Taking it a step further, the company also builds modular buildings (such as portable bathrooms). Here are some photos of the company’s products:

I had a great conversation with Arthur Miles, president of SMID’s Easi-set division, where many of the major products are sold. He joined SMID in 2013 to help drive sales and increase marketing efforts.

He talked about the competitive advantage of some of SMID’s products and how customers can improve margin by choosing SMID over competitors. He is also playing a role in getting more states to approve the use of SMID products (which are currently in 40 states). I was impressed with his knowledge of served markets and realization that increasing marketing spend has been necessary to help take the company to new levels.

During lunch, I had a good conversation with the CFO who joined the company in 2008. We chatted about the new growth opportunities and the favorable conditions that currently exist for the served markets. When I asked him about seasonality, he said it is unavoidable, but that due to their diversified product mix it is less of an issue when compared to the competition.

After lunch, Arthur took me for a ride around the entire outside of the complex so I could take in more SMID products.

Efficiency, Efficiency, Efficiency

Manufacturing companies that find ways to reduce production cost, produce more product with less and make products quicker will see opportunities to expand margins and gain pricing power. That is why in February 2014, SMID hired Mark Loscudo, Vice President of Operations. He guided me through the inside of SMID’s facility. I was very impressed with his commitment to quality control and desire to make SMID’s operations “lean and mean”.

Since he has arrived on the scene, he holds regular meetings with employees to create new ways to streamline processes and generate ways to innovate. We spent over an hour touring the facility.

Wrapping Up The Day

At the end of day, I sat with Rodney Smith. After a brief conversation, Rodney offered to drive me back to my hotel. We chatted for a couple hours about SMID’s beginnings and ways to enhance shareholder value. Rodney was quick to point out that I should notice the difference between the conditions of sound walls as we moved along. The condition of SMID’s product was clearly superior to competitor products, both which had been installed for several years.

A caveat to consider is that the cyclical nature of the business can’t be eliminated and quarters can be lumpy due to timing of large projects and weather. Although, this winter has been relatively mild and management indicated that they lost very little downtime so far.

Overall, I was very impressed with my visit to SMID. Their products are real and appear to have significant competitive advantages. The broad depth of products and exposure to growth currents makes its business less cyclical than I originally assumed. They are already bidding on jobs because of the newly implemented Highway bill; they have opportunity for geographic expansion and they have a high commitment to quality control.

[/hide]