On February 24, 2017, Mikros Systems Corp. (OOTC:MKRS) CEO Tom Meaney sat down with Executive Casts to speak about several topics. Below, he admits that investor communication is important. We also spotlight Tom Meaney’s explanation of how the Navy uses Mikros Systems’ services with respect to its legacy product and condition-based maintenance.

On February 24, 2017, Mikros Systems Corp. (OOTC:MKRS) CEO Tom Meaney sat down with Executive Casts to speak about several topics. Below, he admits that investor communication is important. We also spotlight Tom Meaney’s explanation of how the Navy uses Mikros Systems’ services with respect to its legacy product and condition-based maintenance.

Tom Meaney – It’s Time to Communicate With The Investors

Tom Meaney on the Importance of Communicating with Investors:

Certainly, we do as much as we can to communicate the best we can. We have more of a story to tell now, I feel more confident in what we’re saying, and it’s not just living from year to year but we see real smoothing and I’d love to be able to communicate this in a better way than we have in the past. That’s one of the criticisms they’ve given me, “Come on Meaney, why don’t you tell us more of what you’re doing?”

How The Navy Uses MKRS’ Products (Legacy Product)

Tom Meaney Explains Legacy Product:

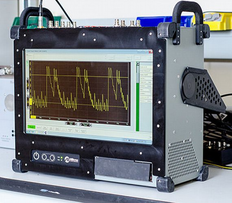

Yes, the big question, the adept equipment was designed for mainly the SPY-1 radar. There’s like eighty Aegis ships that have this radar, it’s a big complex radar. The sailor really needs help so we developed this equipment. It’s about a twenty-three-pound lunchbox computer that was developed for what we call the “Deck Plate.” We had the sailors help us, like where’s their problem? And what this equipment has is seven pieces of general purpose test equipment like oscilloscopes, like power meters, like spectrum analyzers.

There’s like 150 pounds of equipment that lays around in an equipment locker and it’s all integrated into this one equipment that the sailor carries around. And each one of those equipments is on a printed circuit board, instead of a big oscilloscope like this. It’s on a printed circuit board, it’s really a computer, it’s a board computer that we program, with the software engineers, in such a way that it looks like an oscilloscope, and we do that with all these test equipments. So, he walks around with the twenty-three-pound lunchbox computer.

And also, these equipments have to be calibrated every two years or every year and a half because they’re test equipment, we’re actually testing the radar, so we calibrate everything at one time in that box. We do it, the equipment comes back to MKRS, we check it out, we fix it up a little bit and calibrate it, and we send it back. So, we have a rotating pool of these equipments.

How The Navy Uses MKRS’ Products (Condition-Based Maintenance)

Tom Meaney Explains Condition-based Maintenance:

The equipment itself just greatly helps the sailor get through the testing, maintenance, and so on of the equipment. Now, there’s a follow-on equipment, we’re calling it ESQ, and it’s what we call condition-based maintenance. So, it’s slightly different maintenance philosophy. The new LCS ships, they have very few, instead of 250 people on board, they have like sixty. So, nobody can fix anything, really, so what they try to do is monitor everything and send the data back to shore.

So, we’re monitoring the radars, the launchers, the guns, the computers, the radios, continually, twenty-four hours a day, and we’re sending the data back to the beach to be analyzed. So, when that ship comes in after it’s one month at sea, that ship has spare parts waiting for it, this is broken, this was broken, this isn’t working, and then the technicians just swarm all over the ship for a week, get it all ready to go, and bang, it goes out to sea again to fight. So that’s a new philosophy, it’s new with the Navy, so we’ll see how long the Navy operates that way. But that’s called condition-based maintenance.

Now, what we try to do, we use a very powerful technology called Prognostics, and we acquired a small software company to get this expertise within the company, and we’re able to predict when a radar is going to fail. Not exactly, not to the hour, but when it’s running down to the eighty, ninety percent point on life, and so we know roughly how to spare the ship and what to fix next. That condition-based maintenance is being accepted all the way through the military, it’s the big new thing. And we are migrating that into the commercial sector.

You get to a minute here, but basically the Aegis program, and I’m getting very specific now, but they have 250 of these radar directors on all the Aegis ships that actually aim the radar at the target just before the missile is fired. And these equipments, when they go down, the ship goes, yeah, the ship is pretty much neutered and they can’t fight. So, what we’re trying to do is develop a pattern where we can see when they’re going to fail.